service@sequoiahomesllc.com

WHY BACKYARD BUNGALOWS

Avoid complicating the process. Simplify your life.

ABOUT OUR PROCESS

Our success as a Southern California home builder allows us to work efficiently and economically

Backyard Bungalows is responding to the rising demand in California for Accessory Dwelling Units or “Granny Flats” with a product that combines economy, fast delivery, and attractiveness. Homeowners are discovering that California’s new ADU laws allow them to substantially increase home equity, increase functionality, and even add income. Backyard Bungalows makes the decision even easier.

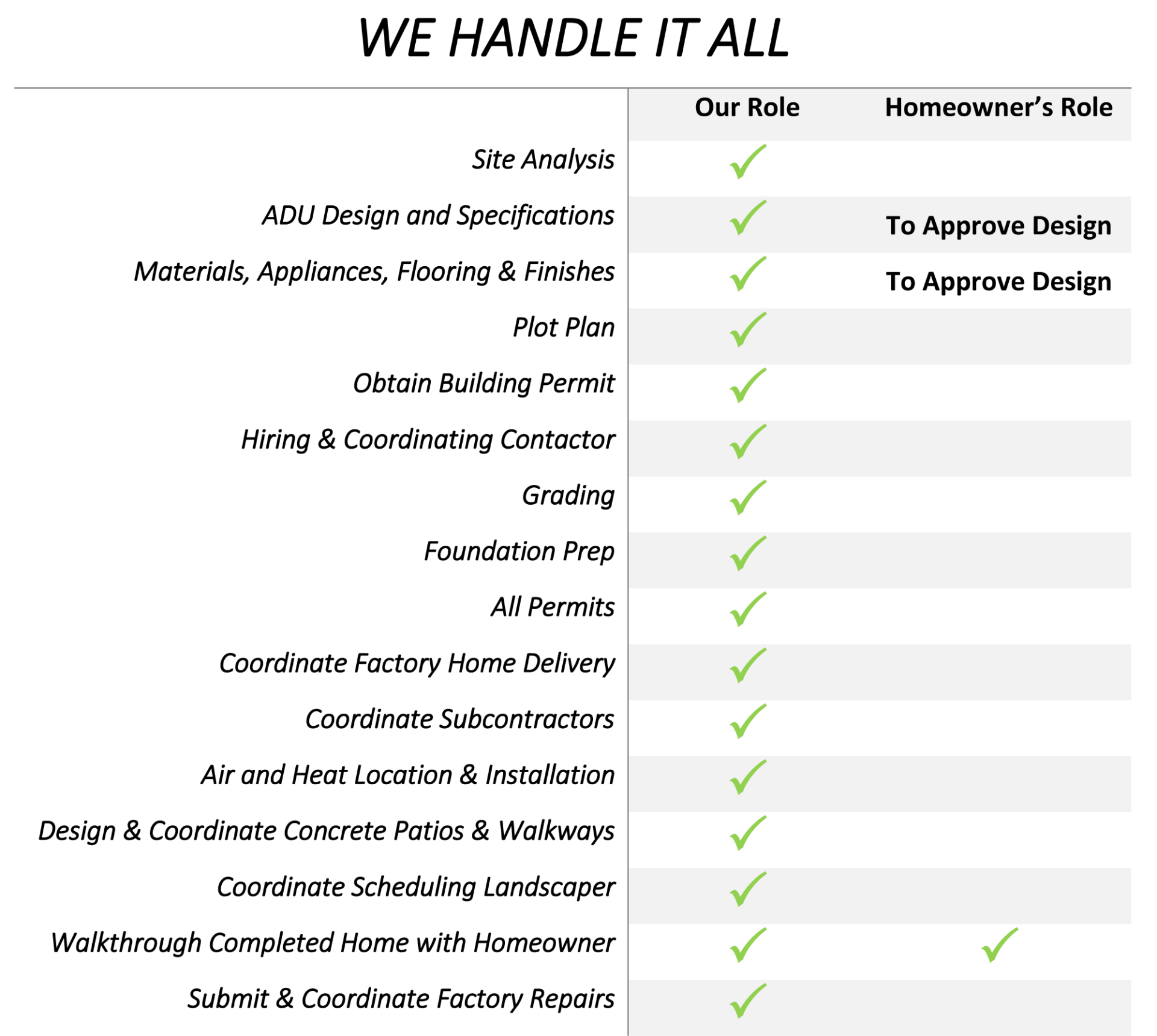

The team at Backyard Bungalows handles an entire project from start to finish. Nothing is left out. You select from a wide variety of floor plans and models. You choose your finishes and options. Backyard Bungalows completes the site plan including connections to utilities. Then we get the permits. We order the home, and our contractor completes the installation. If you need financing, we’ll help arrange that.

MORE ABOUT US

As your factory-built supplier, BB offers a wide variety of pre-engineered plans, sizes, and options that are often already permitted by the local building authority.

FACTORY VS SITE-BUILT

FACTORY-BUILT

If you are looking to build a new accessory dwelling unit entirely from scratch, considering a factory-built ADU is worthwhile. While this option offers the least flexibility in layout and customization, it provides a convenient way to have your ADU constructed entirely in a factory and delivered to you as a finished unit, requiring minimal setup and assembly. You won’t have people coming in and out of your property for months, disrupting your or your neighbors’ schedules, privacy, and security.

As your factory-built supplier, BB offers various plans, sizes, and options, all pre-engineered and often already permitted by the local building authority. You can conveniently select finishes and even appliances from a factory catalog.

Everything, including mechanical, plumbing, electrical, and appliances, is installed at the factory. Numerous energy solutions can also be incorporated into the design of your ADU.

This is an example of a prefabricated ADU being assembled on location.

Factory-built ADUs are often more cost-effective than site-built ones and are reliably priced from the start. Your price is fixed upon signing the contract. Building indoors eliminates weather-related delays. Quality control is ensured, so you won't need to supervise your contractor at the end of each day.

There are two types of factory-built ADUs. Manufactured ADUs are constructed to the federal HUD code, while modular construction adheres to the California residential building code. Following these codes at the factory before shipping the home significantly minimizes delays caused by waiting for building inspector inspections.

SITE-BUILT

Site-built construction requires homeowners to hire an architect and an engineer to design an ADU. After that, the homeowner hires a contractor who employs subcontractors such as electricians, plumbers, roofers, drywall installers, and more. The contractor then purchases lumber and materials to build the ADU from scratch. The entire project is assembled on-site, with one trade following another until the project is completed.

This design and construction method demands significant homeowner involvement in selecting materials, options, fixtures, and appliances.

Conventional stick framing uses considerably more manpower than other methods, as each piece must be measured, cut, and installed. A civil engineer needs to supervise or inspect every aspect of the job to ensure it adheres to the plans.

Conventional site-built construction takes longer and requires more supervision than factory building methods. A longer timeline leads to higher overhead expenses, potential changes in weather conditions, and extended safety risks. Site cleanliness is also a factor since lumber and other materials are cut on-site. However, despite these disadvantages, stick framing offers the greatest flexibility in the design and layout of the ADU. If you want to extensively alter an existing garage into an ADU or add to an existing building, this option is likely the best choice.